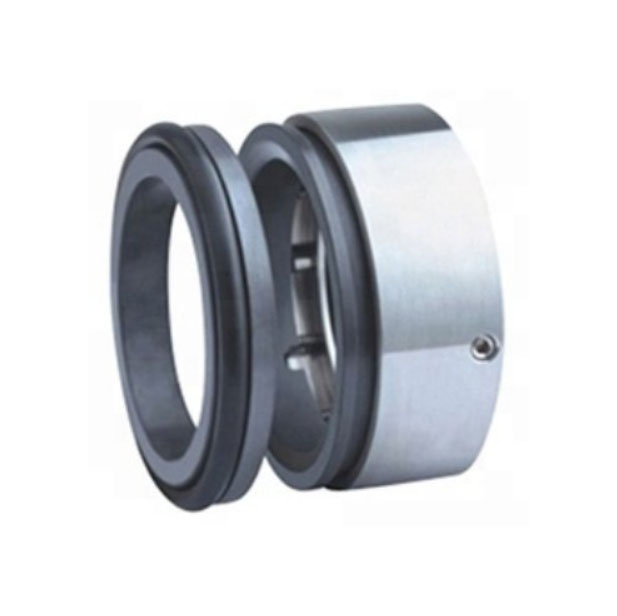

SPRING OUT OF PRODUCT SEAL

MSSRN

Mechanical Seals of the SOP Series are design for media containing solids or with high viscosity Example Sugar, Paper, Sewage & Waste Water Industry. The springs are protected from the media by means of dynamic O ring. This seal requires tightening of stuffing box studs, nuts and detaching of location plate before starting the equipment.

Product Description:

- Single acting Seal

- Balanced design

- Inside mounted

- Independent of direction of rotation

- Stationary springs

APPLICATIONS: (Typical Industrial)

- Sewage Pumps

- Water and waste water Technology

- Sticky and Stringy media

- Chemical Industry

- Pulp and Paper Industry

OPERATING CONDITIONS:

- Shaft diameter: 18.0 .....100.0 mm

- Pressure: 25 bar

- Temperature: -40??C... +260??C

- Speed: 20 m/s

FACE MATERIALS: (Combination)

- Carbon v/s Silicon Carbide

- Tungsten Carbide v/s Tungsten Carbide

- Silicon Carbide v/s Silicon Carbide

METAL PARTS:

- SS 316, SS 304

ELASTOMERS:

- Viton, Nitrile, PTFE, Kalrez

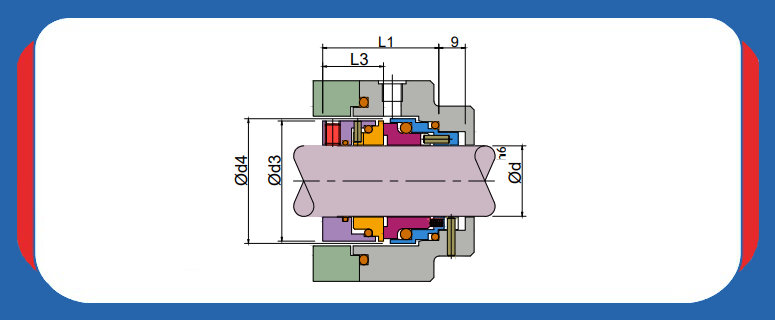

| ??d | ??d3 | ??d4 | L1 | L3 |

| 18 | 33.5 | 34.7 | 37.5 | 19.5 |

| 20 | 35.5 | 36.7 | 37.5 | 19.5 |

| 22 | 37.5 | 38.7 | 37.5 | 19.5 |

| 24 | 39.5 | 40.7 | 40 | 20.5 |

| 25 | 40.5 | 41.7 | 40 | 20.5 |

| 28 | 43.5 | 44.7 | 42.5 | 21.5 |

| 30 | 45.5 | 46.7 | 42.5 | 21.5 |

| 32 | 48.5 | 49.7 | 42.5 | 21.5 |

| 33 | 48.5 | 49.7 | 42.5 | 21.5 |

| 35 | 50.5 | 51.7 | 42.5 | 21.5 |

| 38 | 56.5 | 57.7 | 45 | 24 |

| 40 | 58.5 | 59.7 | 45 | 24 |

| 43 | 61.5 | 62.7 | 45 | 24 |

| 45 | 63.5 | 64.7 | 45 | 24 |

| 48 | 66.5 | 67.7 | 45 | 24 |

| 50 | 70.5 | 71.7 | 47.5 | 25 |

| 53 | 73.5 | 74.7 | 47.5 | 25 |

| 55 | 75.5 | 76.7 | 47.5 | 25 |

| 58 | 78.5 | 80.5 | 52.5 | 28 |

| 60 | 80.5 | 82.5 | 52.5 | 28 |

| 63 | 83.5 | 85.5 | 52.5 | 28 |

| 65 | 85.5 | 87.5 | 52.5 | 28 |

| 68 | 90.5 | 92.5 | 52.5 | 28 |

| 70 | 92.5 | 94.5 | 60 | 34 |

| 75 | 97.5 | 100.5 | 60 | 34 |

| 80 | 105.5 | 108.5 | 60 | 34 |

| 85 | 110.5 | 113.5 | 60 | 34 |

| 90 | 115.5 | 118.5 | 65 | 39 |

| 95 | 120.5 | 123.5 | 65 | 39 |

| 100 | 125.5 | 128.5 | 65 | 39 |

Our Products

- API Seals Type A Arrangement - 1

- API Seals Type B Arrangement - 1

- API Seals Type C Arrangement - 1

- Multi Spring Seals Multi Spring Balanced

- Spring Out of Product Seals

- Stationary High Pressure Seals

- Split Seals

- Conical Spring Seals

- Single Spring Unbalanced

- PTFE Bellow Seals

- Rubber Bellow Seals MSG1, MSG12, MSG13

- Stationary Metal Bellow

- Gas Lubricated Seals

- Dry Running Seal

- Agitator Seals Single Agitator Seals

- Bearing Isolator

- Rotary Joint

- Thermosyphon Pot

- Cryogenic Seals

- Double Mechanical Seals For Anfd

- Mating Ring

- Flushing Plans API-682

Arrangement - 2

Arrangement - 3

Multi Spring Unbalanced

Multi Spring Balanced

Unbalanced With Lug

Balanced

MSR60

Double Agitator Seals

Information Data

Contact Us

MAFFS Seals

Factory Address:

Factory Address:Gala No. 72, Shorab Compound, R.M. Road,

Oshiwara, Jogeshwari (W), Mumbai 400102, India.

Regd Office Address:

Regd Office Address:303, Badhra Apartment, Western Park, Misquita Wadi,

Western Express Highway No. 8, Mira Road (East),

Dist. Thane 401107, India.

Mobile No:

Mobile No: +91-98205 68022

Email:

Email:sales@maffsseals.com

© 2021 www.maffsseals.com | All Rights Reserved.MAFFS

![]()